Custom Manufacturing

- Production according to customer documentation

- We use modern computer technology for processing of technological procedures

- We have a large machinery park

We offer

MEDIUM AND LARGE SERIES PRODUCTION OF TURNED PARTS

MILLING WORK

|

|

|

|

Special workshop

- Complete production of bended and welded parts

- Welding of standard materials, stainless steel, aluminum, bronze, copper and finishing

- Material cutting – max. cut diameter 300 mm, max. sheet thickness 6 mm, max. cutting length 2000 mm

- Hardening and annealing

- Galvanic surface treatment

- Topcoats in RAL colors as required

Assembly

- Assembly of medium size units up to the weight of 500 kg with optional pressure tests

Quality

- Supervisory measurement centre with comprehensive inspection services

- Quality is monitored starting with materials entering the firm; production quality is then further monitored by means of in-process and final inspections

- Inspection is carried out by qualified staff using advanced measurement methods, e.g. by means of 3D machines and other measuring equipment designed for accuracy and quality verification.

- Poličské strojírny a.s. Quality System is certified according to the following standards 9001:2015, EN ISO 14001:2014, BS OHSAS 18001:2007, IATF 16949:2016, the system complies also with the requirements of AQAP standards

Main measuring equipment

- 3D measuring machines Wenzel LH 87, including scanning heads, and Somet XYZ 464 B

- Contact profilometer Hommel – Tester T8000 for profile measurement including roughness

- Authorised metrology centre for verification and calibration of flow measuring gauges with diameters DN 50, 80, and 100, up to the flow rate of 2000 l/min.

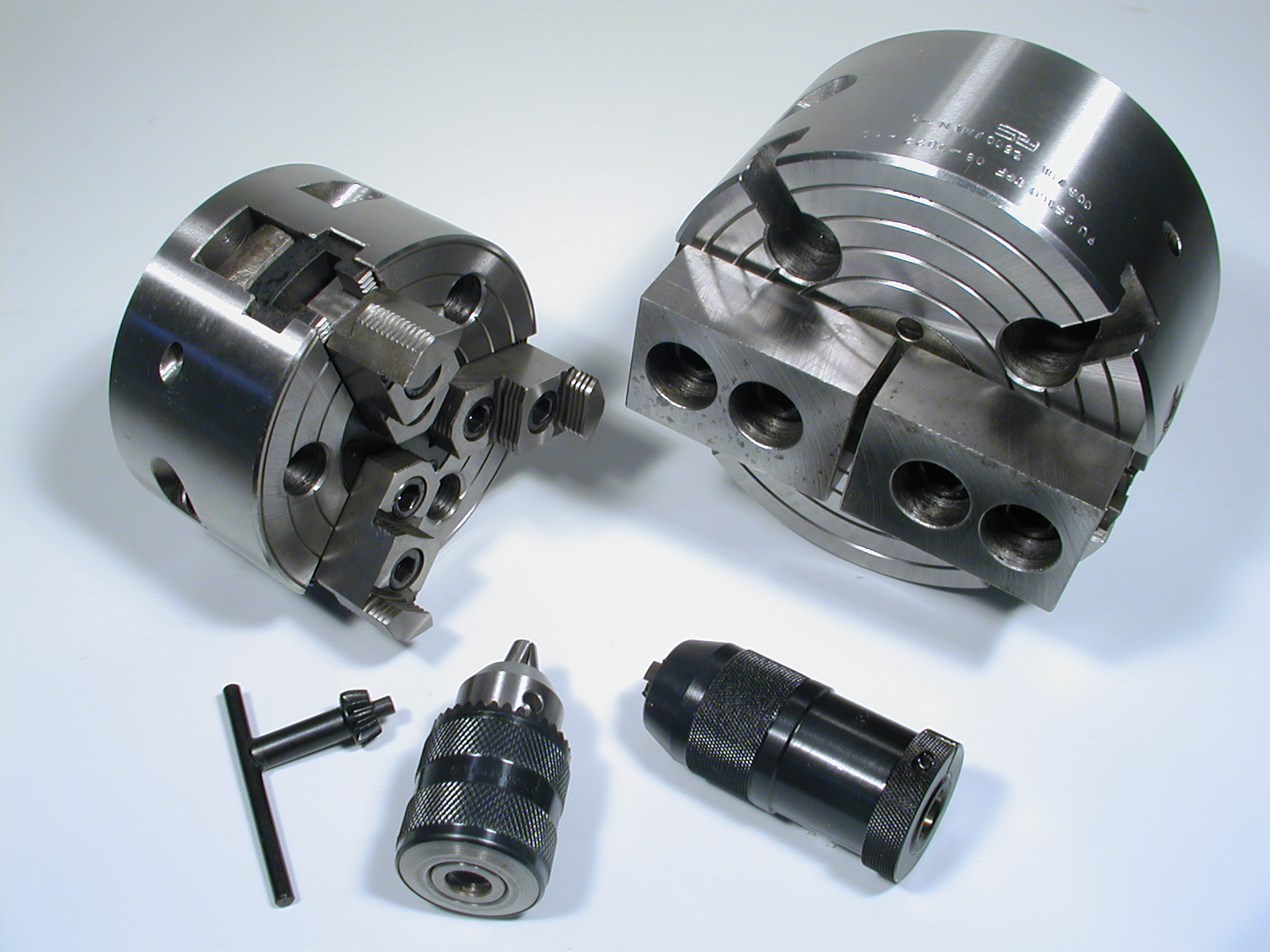

CLAMPING TOOLS

Drill chucks

Pneumatické válce rotační – CLEARANCE SALE

Contact:

Tel.: +420 461 751 549 – Štěpán Krejčí

E-mail: sale@pos.cz